Drawbar

Wagon-Hitch

Ball

Clevis

Hitch-Hook

Piton

Rear 3-Point

NOTE: Set up the ISOBUS control unit in ISOBUS VT before configuring Implement Profile settings.

The display supports two AEF (Agricultural Industry Electronics Foundation)-certified ISOBUS control units. Supported configurations are:

One front implement and one rear implement

Two rear implements, each with up to five operations

NOTE: Up to five implement can be connected; however, when using more than two implements, the number of operations is reduced to two.

The display supports non-linear and multi-rank implements with up to 32 ranks. The AEF ISOBUS implement needs to provide this functionality. Even if the implement supports more than 32 ranks, it must be configured for 32 or fewer ranks. Use the ISOBUS VT to configure the implement.

When selecting ISOBUS VT split screen modules in the Layout Manager application, some modules may show "Initializing" instead of the module content preview.

Using run page layouts with full-size and vertical split screen ISOBUS VT modules for the same implement or control unit is not recommended. The vertical split screen module may not properly react to user inputs when both are on the same run page.

When an ISOBUS control unit is connected, some Implement Profile settings are automatically set by the control unit. Refer to Implement Profile Overview for additional theory of operation.

To complete the setup, enter the following information:

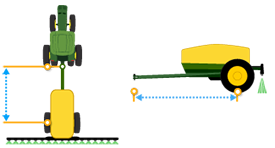

Connection Type, or hitch, describes how the implement is attached to the machine and controls how the display determines the implement movement behind the machine.

NOTE: Connection offset measurements are entered in Machine Profile.

The following applications require Connection Type setting:

Mapping

Section Control

Work Setup

|

|

Drawbar |

|

Wagon-Hitch |

|

|

Ball |

|

Clevis |

|

|

Hitch-Hook |

|

Piton |

|

|

Rear 3-Point |

|

|

Some implements have a pivoting hitch that connects to the machine rear 3-point hitch. The offset for this pivoting location is required for the display to determine the implement movement behind the machine.

NOTE: Pivot Offset setting is available when Rear 3-Point is selected as the Connection Type.

Instructions for Measuring Pivot Offset

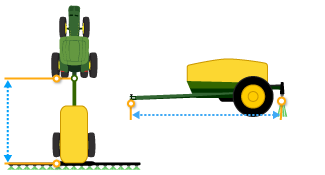

In-line distance from the connection point to the implement Center of Rotation while in working position. Usually, this is where the load-bearing parts of the implement make contact with the ground.

In-line distance from the connection point to the implement Center of Rotation while in working position. Usually, this is where the load-bearing parts of the implement make contact with the ground.

The Center of Rotation offset is important to accurately model the trailing action of the implement around curves.

NOTE: This offset is NOT needed if the Connection Type is set to Front 3-Point or Non-Pivoting Rear 3-Point.

NOTE: When using an AEF-certified control unit with the Product Applicator machine profile, set the Center of Rotation to 0.

The following applications require the Center of Rotation setting:

Mapping

Section Control

Work Setup

Guidance

AutoTrac Turn Automation

NOTE: Measure the Center of Rotation while the implement tool is engaged.

Instructions for Measuring Center of Rotation

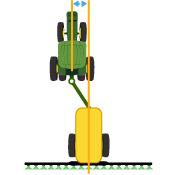

In-line distance from the connection point to the point where product is dropped.

In-line distance from the connection point to the point where product is dropped.

NOTE: When using an AEF-certified control unit with the Product Applicator machine profile, set the Work Point only on the machine profile and not the implement profile.

Select the type of work point for the operation.

|

Linear Work Point |

|

|

Non-Linear Work Point |

|

NOTE: Non-linear work point is selected by default if the functionality is supported by the implement.

The following applications require Work Point setting:

Mapping

Section Control

Work Setup

Instructions for Measuring Section Offset

Lateral distance from the center point of the machine to the center point of the working width of the implement.

Lateral distance from the center point of the machine to the center point of the working width of the implement.

NOTE: When using an AEF-certified control unit with the Product Applicator machine profile, set the Lateral Offset to 0.

The following applications require Lateral Offset setting:

Mapping

Guidance

Instructions for Measuring Lateral Offset

Mechanical Delay is the average time for the product to reach the ground after an ON or OFF command. It may need to change with each machine, implement, and display combination.

The following applications require Mechanical Delay settings:

Mapping

Section Control

Work Setup

Instructions for Measuring Mechanical Delay

Coverage Map is the setting used to adjust the map coverage behavior of the implement. It may be set to Actual Rate or Section Control.

|

Select to change the Coverage Map setting. |

|

NOTE: It is recommended to use the Actual Rate option.

|

Select the Reset Profile button to delete the current implement profile settings. |

|

If an implement is connected, settings stored on the implement control unit are loaded to the display.

NOTE: If an implement profile fails to load properly, select Reset Profile button to reload settings.

Add an implement receiver or edit receiver offsets.

|

Select the Add Receiver Mount button to add an implement receiver. |

|

Select the receiver offsets to edit implement receiver offsets.