Machine Profile settings are important for the accurate performance of John Deere AMS applications, such as AutoTrac and Section Control.

Items accessible on the Machine Profile page:

NOTE: If the display detects a machine, some information is automatically set by machine controllers.

Profile name, machine type, and serial number are displayed on the General tab.

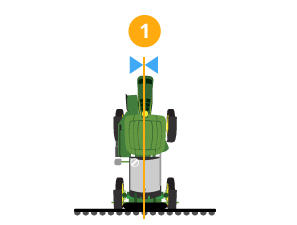

Lateral Offset

Lateral OffsetLateral offset is the lateral distance from the center point of the machine to the center point of the GPS receiver.

The following applications require Lateral Offset:

Guidance

Coverage Map

Instructions for Measuring GPS Lateral Offset

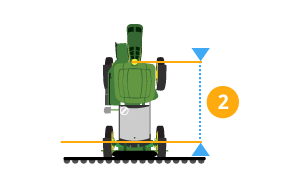

In-line Offset

In-line OffsetIn-line Offset is the in-line distance from the rear axle to the GPS receiver.

The following applications require In-line Offset:

Documentation

Section Control

Guidance

Instructions for Measuring GPS In-line Offset

Working Width is the width of the area sprayed on each pass through the field. It is used to create coverage maps and calculate the area worked.

The following applications require Working Width:

Guidance

Coverage Map

Area Totals

Determine Working Width by entering the nozzle count and nozzle spacing.

|

Select Boom & Nozzle Settings to view and edit boom section settings, such as nozzle count and nozzle spacing. |

|

Sprayers equipped with multiple tanks can be configured to use these tanks either in combination or independently.

|

Select Tank Configuration to view and select single or dual tank configurations. |

|

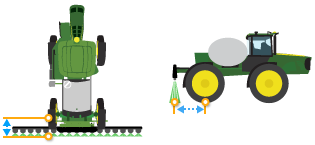

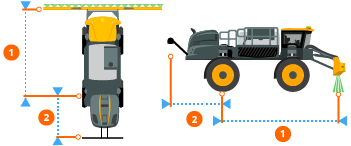

Work Point is the distance from the center of the rear axle to the location where product is applied.

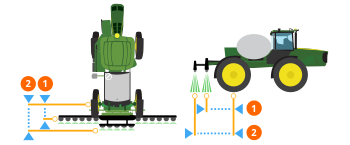

Some boom configurations use two work point measurements.

Boom (1) and Center Frame (2) work points are the distance from the center of the rear axle to the location where product is applied.

Front Boom (1) and Rear Boom (2) work points are the distance from the center of the rear axle to the location where product is applied.

NOTE: If your Hagie sprayer is equipped with a rear boom but it is not an option, make sure that the rear boom is activated on the Hagie display and cycle the key. After activating, a second work point is available for the rear boom.

The following applications require Work Point:

Section Control

Work Data Maps

Mechanical Delay is the average time for product to reach the ground after an ON or OFF command. It may need to change with each machine, implement, and display combination.

The following applications require Mechanical Delay:

Section Control

Work Data Maps

Instructions for Measuring Mechanical Delay

Direct Injection Pump provides a method for mixing product into the fluid pumped from the solution tank to the boom nozzles. Operator can adjust the application rate by introducing product directly into the solution using this system.

|

Select Direct Injection Pump to view and edit settings. |

|

|

Select Save button to store settings from all tabs and close the Machine Profile application. Selecting Save is not required when switching between tabs. |

|

Default sprayer profile settings are stored in sprayer controllers. Changes to these settings are stored in the display.

|

To reset profile to factory defaults, select Reset Profile button. |

|