This value is usually set to 0.0 unless GPS receiver is offset left or right of machine center line. An operator may also adjust this value if the machine (without an implement) has pass-to-pass AutoTrac accuracy issues. In this case, use the following procedure to measure GPS Lateral Offset for all machine types.

NOTE: Before adjusting this setting, ensure proper GPS receiver TCM calibration, tires inflation, and machine ballast. Failure to do so may result in inaccurate measurements.

Disconnect implement or remove implement from the ground. Implement should not affect machine movement.

Set up a Straight Track guidance line.

Engage AutoTrac and drive along the line. Stop at a few points to mark the center of the machine (drawbar) with a flag.

Turn around, engage AutoTrac, and drive over the same track in the opposite direction. Stop at each flag.

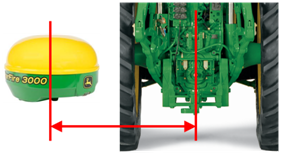

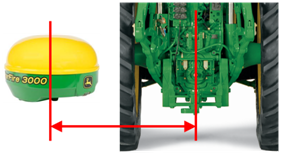

Measure distance between center of machine and each flag. If this is a pass-to-pass issue, there should be a relatively equal distance at each flag throughout the entire pass.

If these measurements are within advertised accuracy of system (SF1, SF2, SF3, SF-RTK, RTK), do not change this offset. Instead, check Implement Lateral Offset.

Otherwise, divide measurement in half to determine GPS Lateral Offset.

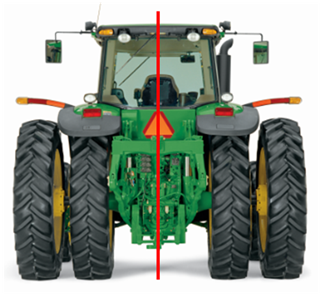

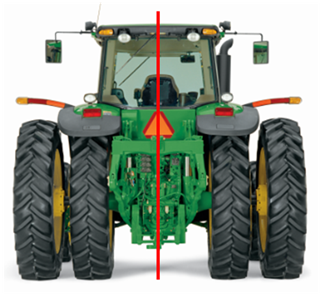

NOTE: If tractor needs to drive to the right of its current path, toggle offset direction on display to the right. Move GPS receiver on tractor image to right side of center line.

Repeat steps 2 through 4 to determine if offset amount and direction were set properly.